Honours & Awards 2010

Presidents Address

Awardees, Sponsors, Ladies & Gentlemen; I would like to welcome you all here this evening to our Annual Honours and Awards Ceremony which is conducted to acknowledge and encourage excellence for those training for careers in Instrumentation, Systems and Automation, and also to express our thanks and recognition to those who have led the way in the pursuit of their careers in those fields.

Awardees, Sponsors, Ladies & Gentlemen; I would like to welcome you all here this evening to our Annual Honours and Awards Ceremony which is conducted to acknowledge and encourage excellence for those training for careers in Instrumentation, Systems and Automation, and also to express our thanks and recognition to those who have led the way in the pursuit of their careers in those fields.

Education & Training continues to be a Cradle to Grave concept, and one which ISA embraces from its founding ethos. Access to education is not freely available across the whole of this world. Therefore one cannot over emphasise the value of education and on which I truly believe has always rested the future of mankind.

Being educated places a large responsibility on one to pass on the knowledge gleaned to others during our life journey. However the full appreciation of this gift only becomes more apparent towards the end of ones life. In that process the role of educator oscillates between our parents, school teachers, sporting and social leaders, college lecturers and work place mentors to varying degrees as we evolve through life with the resulting impression that we are at once and always both educator and student.

Irish industry has been a bedrock sponsor of ISA Ireland Section activities throughout the past thirty years of our existence. We are delighted that this support has continued for this ceremony and that each sponsor is represented here this evening, clearly demonstrating industry awareness and support for promoting and awarding excellence. I would like to pay a special word of thanks to this evening’s sponsors:

- DPS Engineering

- RPS Group

- O’Sheas Electrical

- Valve Services

- Shering Plough, (Brinny)

- Jansen Pharmaceuticals

I am honoured to be here in my capacity as President of ISA Ireland Section and to present the awards which represent a tremendous achievement for the recipients and especially to be so honoured in the presence of their mentors and their peers.

This year we have five awards, four of which have been nominated by Third Level institutions and one from the membership of our Section. Therefore I would like to specifically welcome the award recipients and their families

To conclude I would like to pay a special word of thanks to our organising committee, to the judging panel, the participating colleges and finally to UCC for allowing us to use this very historic “Common Room†this evening.

Thank you all for attending and supporting this auspicious function. I hope you all have a very relaxed and enjoyable evening as we celebrate excellence in our industry.

I would like to leave you with these words from William Butler Yeats:

“Education is not the filling of a pail, but the lighting of a fire.â€

David O’Brien

ISA Ireland Section President

Craftsman Award

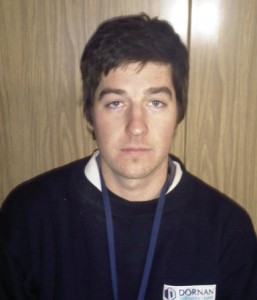

Recipient: Mr. Eoghan Geary, Ballyduff, Co. Waterford.

Nominated by: Mr. Jim Doyle, Lecturer, Institute of Technology Carlow.

Eoghan served his apprenticeship as an Instrumentation/ Electrical craftsperson with Dornan Engineering, Little Island, Co. Cork. From August 2007 to-date he has completed phase 2/4/6 in Cork FAS and Carlow Institute of Technology. From day one his attitude and commitment was exceptional.

Eoghan served his apprenticeship as an Instrumentation/ Electrical craftsperson with Dornan Engineering, Little Island, Co. Cork. From August 2007 to-date he has completed phase 2/4/6 in Cork FAS and Carlow Institute of Technology. From day one his attitude and commitment was exceptional.

The Electrical/ Instrumentation phase 6 class (March – June 2010) were an exceptionally good group of apprentices. However Eoghan stood out from the rest, for his very good class work, attention to detail and leadership qualities in the class. His individual results in each topic were the highest in a very competitive group and for this I would have no hesitation in nominating him for the award.

His lowest mark in the six examinations in phase 4 was 96% with the class average between 82 % and 85%. In phase 6 his lowest marks was 97% with the class average being between 80% and 82%

Degree Award

Recipient: Mr. Gary O’Halloran, Mallow, Co. Cork.

Nominated by: Dr. Liam McDonnell. Head, Department of Applied Physics & Instrumentation, Cork Institute of Technology.

Honour’s Degree Award

Recipient: Ms. Nichola Walsh, Christchurch, Dublin 8.

Nominated by: Dr. Enda McGlynn. Department of Science, Dublin City University

It is the wish of the staff of the School of Physical Sciences in DCU to nominate Ms. Nichola Walsh (who recently graduated from the B.Sc. (Hons.) in Applied Physics Degree programme. Primarily for her outstanding fourth year project entitled “Psycho acoustic Delay Generator â€, which we feel is an excellent example of the application of physics to an important problem in a domain not normally regarded as “core physics†demonstrating the breadth of skills and potential contribution of applied physics graduates.

It is the wish of the staff of the School of Physical Sciences in DCU to nominate Ms. Nichola Walsh (who recently graduated from the B.Sc. (Hons.) in Applied Physics Degree programme. Primarily for her outstanding fourth year project entitled “Psycho acoustic Delay Generator â€, which we feel is an excellent example of the application of physics to an important problem in a domain not normally regarded as “core physics†demonstrating the breadth of skills and potential contribution of applied physics graduates.

Nichola had to utilize her core physics knowledge and abilities while learning how to deal with the necessities of a new application area (including challenges such as ethical approval issues, for tests on human volunteers) and she dealt with all these issues with great professionalism. Furthermore, the project developed instrumentation for the quantification and analysis of a challenging issue in the domain of psychoacoustics which puts it squarely in the domain of the ISA in our opinion. For both these reasons we feel that Ms. Walsh should be considered for the Honours Degree award of the ISA – Ireland Section. We also note that Nichola’s project has been awarded the Fryar medal from DCU for the outstanding final year project across all physics degree programs.

Non-organic hearing loss is the term used to describe the deliberate exaggeration of hearing loss. One method which may be used to test for fraudulent claims of this nature is by means of a psycho acoustic delay. Varying the time delay between speech production and audio playback produces varying degrees of speech interference effects.

The aim of the project was to construct a device to delay speech which could be used to locate the time delay corresponding to the maximum interference of fluent speech. . Initially a programmable dsPIC microcontroller was implemented as the method by which to delay speech but a more suitable alternative solution was judged necessary based on initial trials. Therefore a program was created using LabView to implement the audio delay and a speech analysis software package used for subsequent recording and analysing of the recorded data. A subject study of 28 volunteers was carried out and the time delay resulting in maximum interference of fluent speech was found to be 200ms.

An analysis of disfluency levels, reading rates and intensity variations were carried out. Age and gender assessments were performed under delayed feedback conditions. No significant dissimilarities were found in disfluencies occurring for different age groups. Notable disparities were observed between males and females which were theorised to be caused by the variations in intensity detected. Reading rates for all subjects tested were found to decrease under delay conditions.

A full technical project report (74 pages) was submitted at the end of semester 2, in addition to a presentation and a literature survey. Both of these were submitted for this award.

In addition to Nichola’s fourth year project, we also summaries the relevant aspects of her overall academic performance, which included results between 72% and 80% in six subjects in her fourth year. Resulting in a final degree classification 1st class Honours (H1).

Post Graduate Degree Award

Recipient: Mr. Ciaran Peyton, Swinford, Co. Mayo

Nominated by: Professor Loraine Hanlon. School of Physics University College Dublin

The contributions for which the above named nominee should be recognised are: Thesis on: Portable Spectrometer System for Characterising the Optical Properties of Water. Thorough analysis of the technical requirements at the component level to construct a cost effective spectral reflectometer system for non-contact water optical property determination.

The contributions for which the above named nominee should be recognised are: Thesis on: Portable Spectrometer System for Characterising the Optical Properties of Water. Thorough analysis of the technical requirements at the component level to construct a cost effective spectral reflectometer system for non-contact water optical property determination.

Complete re-analysis of optical technology options back to first principles ending with a system combination of off-the-shelf components meeting measurement objectives at a fraction of the cost of previous prototypes.

Development of ultra-sensitive signal integration processes using multiple frame analog video capture. Thorough re-evaluation of the underlying radiative transfer processes which describe the science behind the detection of optically distinctive constituents in water bodies; leading to an integrated system capable of non-contact and fouling free estimation of water constituent concentrations. Instrument concept ‘know-how’ now incorporated into a license agreement between UCD and Spectral Signatures Ltd. Ciaran has three papers under preparation for publication on theoretical and validation aspects of the study.

The European Science Foundation’s number one recommendation on the remote sensing of coastal environments is to enhance the quality and quantity of the basic ecosystem parameters retrieved from optical measurements. Satellite remote sensing in these areas provides insufficient results due to the influence of the sea bed on the remotely sensed light, the variation in the depth of the water and the high concentration of constituents entering the water from the land.

This thesis details the development of an in-situ active portable spectrometry system capable of sampling across the whole visible spectrum at spectral resolutions down to a few nano meters for remote sensing of the optical properties of water. This submersible system also provides the capability of monitoring the optical properties within the water column by giving a profiling capability.

A computationally light weight Radiative Transfer Model (RTM) based on Chandrasekhar’s solution to the radiative transfer equation in planetary atmospheres has been developed for water application. This model is shown to provide estimates of basic ecosystem parameters in waters of varying depth with a lambertian reflecting bottom. The RTM model has been adapted to the spectral resolution of the instrument and comparisons between model and instrument system measurements for a number of constituent scenarios are described.

These include water samples containing varying levels of chlorophyll-a and scattering particulates and observation modes involving water layers of varying depth and of varying thickness.

By minimising the difference between model predictions and corresponding measurements, constituent concentrations have been estimated and compared with independent concentration measurements. Producing correlation coefficients better than 0.96 in all cases. This simple RTM, incorporated into minimisation based inversion method, can be applied to real measurements to estimate constituent levels in waters of varying depths and has applications in remote sensing and profiling of open ocean and coastal waters.

Instrumentation Pioneer Award

Recipient: Mr. Peter McDonald, Kinsale Co.Cork

Nominated by: Mr. John Sweeney and by Mr. David O’Brien

With Eli Lilly in the early 1980’s Peter supported the introduction of computer automation to the Kinsale site. In its time this was a major advance in manufacturing thinking. Kinsale was one of the first Lilly bulk manufacturing plants to be automated. Continuous control and sequential operations were for the first time built and coded into a computer processor unit and through human machine interfaces were manipulated by operations personnel. The plant witnessed in turn the power of faultless repetition of processing tasks which was to become the foundation of manufacturing excellence. Peter was to the fore in introducing, troubleshooting, integration and management of this early automation system.

With Eli Lilly in the early 1980’s Peter supported the introduction of computer automation to the Kinsale site. In its time this was a major advance in manufacturing thinking. Kinsale was one of the first Lilly bulk manufacturing plants to be automated. Continuous control and sequential operations were for the first time built and coded into a computer processor unit and through human machine interfaces were manipulated by operations personnel. The plant witnessed in turn the power of faultless repetition of processing tasks which was to become the foundation of manufacturing excellence. Peter was to the fore in introducing, troubleshooting, integration and management of this early automation system.

In the mid 1980’s the automation system was upgraded to Distributive Control System (DCS). Peter was the driving force behind this change which led to an explosion of use in control systems across the site. Peter continued to be the key resource to introduce and shake down this new technology and through his exploitation of fiber optic technology to knit these systems together into a process automation network for the site. Peter supported the drive and desire to automate processes which in turn improved productivity and raised throughput.

Also in the late1980’s Peter developed and introduced an on-line Ozone detection system for use in a production process. This was a first for Lilly and ultimately enabled a continuous process to be set up which would have been unthinkable without this technology. This was replicated at other plant sites. It was in effect one of the first processes to have an online process analytical technology (PAT) solution.

The site in the early 1990’s became increasingly interested in lowering the quantity of volatile organic material released from site manufacturing operations and embarked on a project to install one of the first regenerative thermal oxidizers for this purpose. Critical measurement of % volatile organics for the safe operation of this system was designed and installed by Peter utilising an online / real-time infrared detection system which is still the basis of operation and safety to this day. This combined with a safety instrumented explosion suppression system and a calorimetric gas analyzer has also been in operation with this duct and thermal oxidizer unit since start-up. Peter has expanded this fume capture system to cater for the addition of new manufacturing facilities and the basic design concept has been robust and enduring over its service life and has been able to cater for these changes.

Peter was requested to install online incinerator stack gas analyzers to measure residual carbon monoxide, chloride and hydrocarbon content of stack gases. Peter sourced, installed and commissioned this new array of process analytical technologies to assist site operations to be ready for the emerging European legislation which would govern the operation of incineration plant. Peter has maintained and upgraded this equipment over the years and has formed a contract with the German National Air Monitoring board for periodic calibration and certification of this vital compliance equipment.

Peter has combined this measuring capability with a recognized data analysis capability (plc based) to continuously analyze and predict on a real time basis incinerator performance and ensure that hourly and daily expectations with respect to stack gas emissions are met. This combined system is programmed to interrupt incineration operations automatically and remove the permissive for a restart until a sufficient interval has elapsed to restore the site to a compliant footing for a given time interval.

Increasing expectations around continuous monitoring of liquid effluent and gaseous emissions led Peter to introduce incinerator stack gas particle analysers and continuous hydrocarbon monitors for ground water flowing from the site. Peter was responsible for the design and introduction of the burner safety management systems for the incinerators both liquid, solid and fume that have been introduced to the site down through the years.